Flexible Installation Verification

RiserTec Scope of Work –

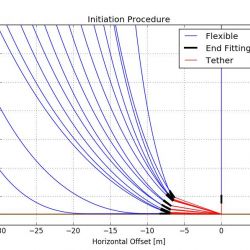

Basic methodology is fairly standard and involves data review and screening of vessel motions to identify worst case motions for different headings over a realistic range of periods. By adjusting range of laybacks we can determine widest installation window and confirm feasibility of the initiation, lay and lay-down stages. Based on final agreed values of seastate and layback it is possible to produce lay tables and other output such as curve allowable radii, maximum expected chute and seabed tensions and vessel and seabed object clearances. In addition optimum vessel setup can be identified for the actual wave and current occurring during the onsite installation.

The purpose of the work is to identify to the client what are the critical aspects of the procedure (risks) and the possible steps available at each stage to take should for example something go wrong with installation equipment or vessel so that the product is not damaged.

RiserTec has carried out original and verification analyses for both Operator and Installation Contractors for both rigid and flexible pipes, cables and umbilical in both the Oil and Gas and Renewables sectors. If required we can generate the installation procedures and lay tables for initiation and abandonment.

In addition to the lay analyses we can carry out trenching analyses and on-bottom roughness assessment for flexible and rigid flowlines and including where required UHB assessment for as laid conditions.

Latest News

Oct-2021

Wind Turbine Design Development

RiserTec has been involved with the research & development of a new design of Offshore Wind Turbine support and mooring structure. The aim of the design is to provide a cost effective solution to the transport to site and support issues of Offshore Wind Turbines via the innovative use of existing technologies which are already industry recognized. Concept designs are being produced with the view of acquiring approval for further development by the relevant industry regulatory bodies.

read more >

Nov-2020

COVID

Throughout the COVID-19 Pandemic, RiserTec's primary concerns have been with safety of its employees and customers. To combat these issues RiserTec remains fully operational via the use of remote working processes and increased safety measures during times where working within close proximity to others is required.

read more >

Oct-2020

Deep Water Riser

RiserTec has been involved in the engineering and design of a new subsea system intended to harvest critical base metal nodules from the seafloor. RiserTec's involvement over the period of around 1 year so far has mainly been in the global analysis & fatigue analysis of the lifting system that will carry the nodules from the seafloor to surface, with its main component being a 4.5km riser. The nodules contain high grades of nickel, manganese, copper and cobalt - key metals required for building electric vehicle batteries and renewable energy technologies.

read more >

Sep-2020

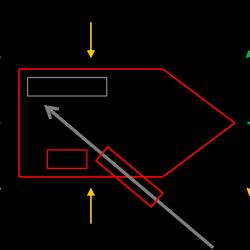

MWA Tether Padeye Replacement

RiserTec was involved with the engineering and design of a replacement MWA tether base padeye for a major north sea operator, and the operation of replacing this component in-situ within the riser system at several site locations. The original component had suffered from fatigue damage as predicted in an earlier assessment, requiring a new billet component to be designed and installed. Extensive analysis work was carried out in order to identify the optimum method of replacing this component, before designing and fabricating temporary tether point structures to use in the replacement operation.

read more >

Sep-2019

RiserTec acquired by Oil States Industries

RiserTec has recently been acquired by Oil States Industries, a major global provider of integrated energy systems and solutions.

OSI has the capability & expertise to enable customers to build and operate high-performance offshore facilities and offers a full range of solutions for the most demanding environments from project start to finish. Against this background, RiserTec will continue to operate as a fully independent division within OSI providing riser, mooring and pipeline system engineering and analysis services to both existing and new Clients.

With leading-edge technologies and unsurpassed technical expertise, OSI can deliver reliable, cost-effective solutions to meet drilling, workover, production, lifting and mooring challenges & has a strong track record of supporting customer success for over 75 years. The addition of RiserTec to the group will greatly enhance OSI’s subsea engineering capabilities while at the same time providing RiserTec with significantly increased commercial backing plus access to OSI’s large procurement network.

read more >

Jun-2017

ISO 9001 Transition

RiserTec’s Quality Management System is currently transitioning into the new ISO9001:2015.

read more >

Jun-2017

RiserTec Website Update

The launch of the new RiserTec website is designed to bring viewers a new insight into our Engineering & design capabilities. Please visut us soon for frequent updates regarding new developments, news & vacancies within the company.

read more >

Nov-2022

Wind Turbine Platform Wave Tank Testing

An offshore wind turbine support structure conceived by RiserTec has entered the model testing phase. A 1:50 scale model of the Fixed TLP (FTLP) concept has been tested under operational and extreme wind and wave conditions. Test data is being processed for system evaluation and to support future optimisation before progressing to the next stage of the design process. The final design is planned to support a 15MW wind turbine in water depths up to and exceeding 100m.

read more >

Nov-2022

Rare Metal Nodule Collection

Nodules rich in rare metals required for electrical batteries have been collected from the sea floor through a 4.5 km long riser designed and analysed by RiserTec. 14 tonnes of nodules were collected from the sea floor and delivered to the production vessel during a 60-minute trial of the system. RiserTec’s role was global riser analysis and fatigue performance assessment.

read more >

Oct-2023

Rare Metal Nodule Collection

Nodules rich in rare metals required for electrical batteries have been collected from the sea floor through a 4.5 km long riser designed and analysed by RiserTec. 5000 tonnes of nodules were collected from the sea floor and delivered to the production vessel during a 6 month trial of the system. RiserTec’s role was global riser analysis and fatigue performance assessment.

read more >